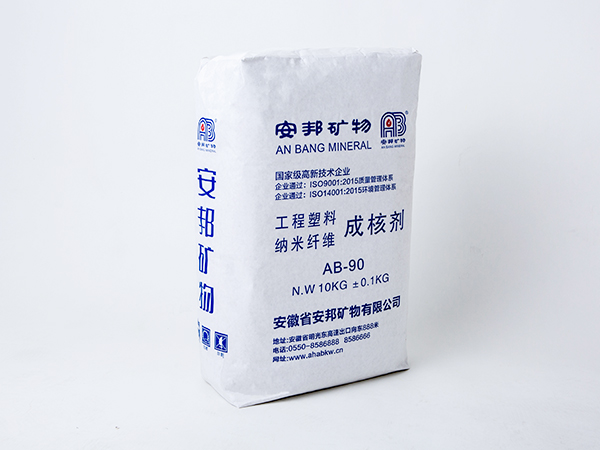

Nucleating agent for engineering plastics nanofibers AB-90

Product details

Engineering plastics nanofiber nucleating agent (suitable for PA, PP, pet, PE, POM)

1、 Product introduction

Ab-90 is a kind of nano nucleating agent and reinforcing agent. It has natural nano fibrous silicate minerals with purity up to 99%, particle size of 20-50nm and length of 500-1500nm. It is prepared by scientific surface treatment. The main components are attapulgite clay (nanorod crystal structure, high temperature resistance, anti-aging and other good properties). It can absorb a lot of harmful gases and smoke from the combustion of rubber, plastics and other polymers.

2、 Product application features

1. With high crystallinity and uniform size distribution, the mechanical and thermal properties of the materials have been greatly improved.

2. Nanorod nucleation, polymer penetration into the nucleating agent micropores, non oriented nanofiber grade crystal nucleus in the matrix greatly improves the stability and anti displacement ability of crystal nucleus, stable size and outstanding anti warpage performance, which improves the dimensional stability of products.

3.Greatly shorten the molding cycle, improve productivity, excellent demoulding performance. (both the modified brace and the product molding have extremely high crystallization rate).

4. Reduce the shrinkage of the products, prevent the stress cracking of the products, and improve the surface gloss of the products.

5. It has passed food and drug grade certification, meeting the higher environmental protection requirements.

6. Excellent surface treatment and high-efficiency surface energy can promote the nano materials to be evenly dispersed in the materials without agglomeration, so as to overcome the problems of easy agglomeration and uneven dispersion of nano materials, and completely release the nano effect.

high performance product properties not only exist in unreinforced materials, but also in reinforced materials, especially suitable for glass fiber reinforced polyester. The reason for these effects is that compared with glass fiber, it can form more fine and uniform nano fiber and rod crystal structure in polyester matrix. It is the comprehensive performance of mesoscopic system with surface effect, volume effect, quantum size effect and macroscopic quantum tunneling effect. It can increase the peak value of thermal crystallization to 210 ℃ in pure resin.